Share this on:

Product Introduction

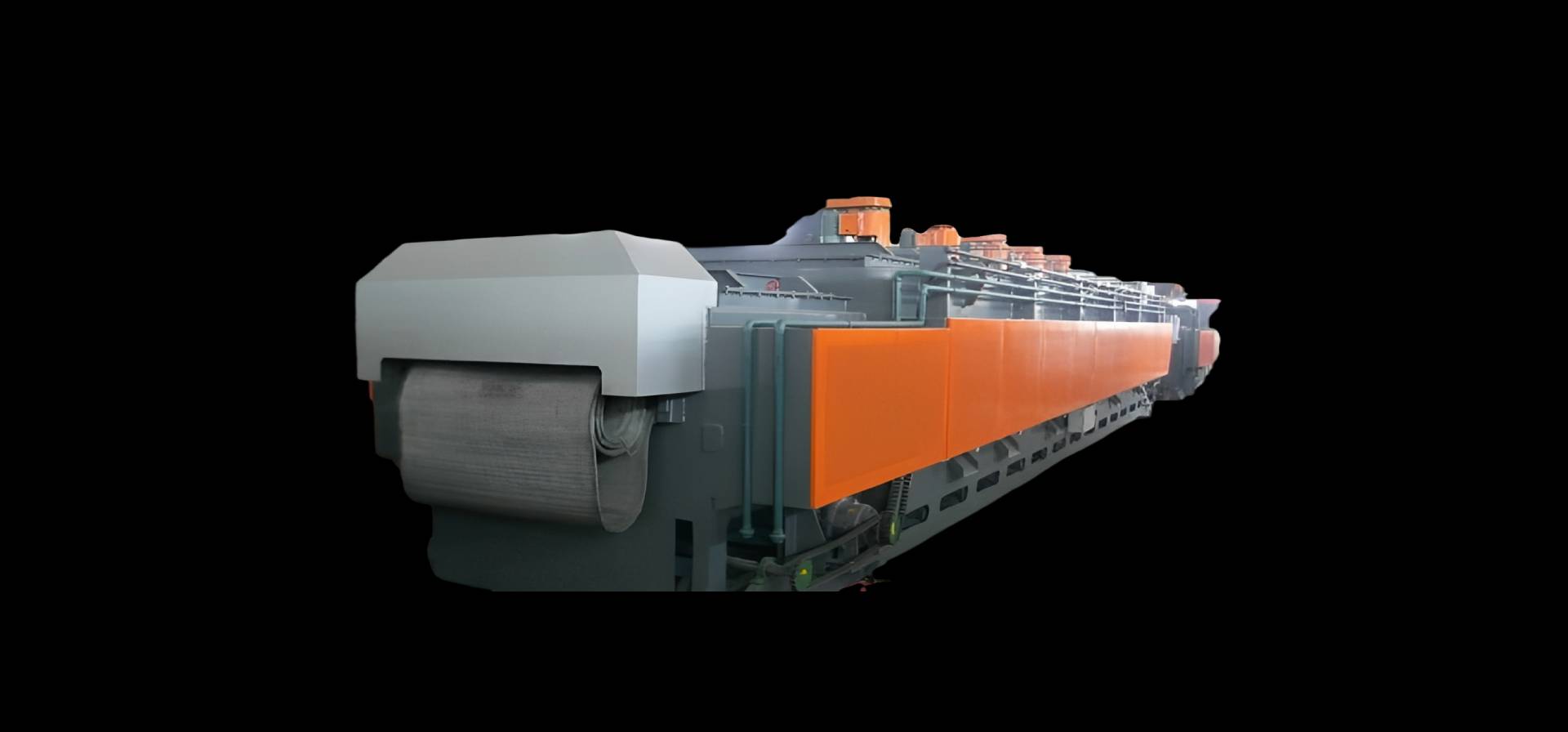

Technobel Oven’s industrial heat treat ovens and tempering ovens are available in either gas-fired or electrically heated different temperature ranges. The standard maximum continuous temperature ratings offered are 800°F (425°C), 1000°F (540°C), 1250°F (675°C), and 1400°F (760°C). Industrial heat treat ovens and tempering furnaces are commonly referred to as Companion Draw Furnaces or conveyor ovens. Oven’s draw batch ovens feature heavy-duty furnace construction, which includes a plate steel outer shell, a reinforced steel plate oven front, a lined inner shell, and exterior structural reinforcements as required. When specified, the equipment can be designed to meet even the most stringent Tempering of fastners:- About 90 percent of fasteners are steel based and the required strength level is usually developed in steel fasteners using quenching and tempering processes. Accordingly, the terms “high strength” with “heat treated” or “hardened” are often equivocated with the fastener world. However, heat treatment includes a wide range of processes. Some heat treatments like annealing soften a metal, while others harden and strengthen. Annealing heat treatments are used to relieve residual stress, remove cold work and dissolve the alloying element or segregation and provide a more homogeneous material.

Industrial heat treat ovens and tempering furnaces feature: