Share this on:

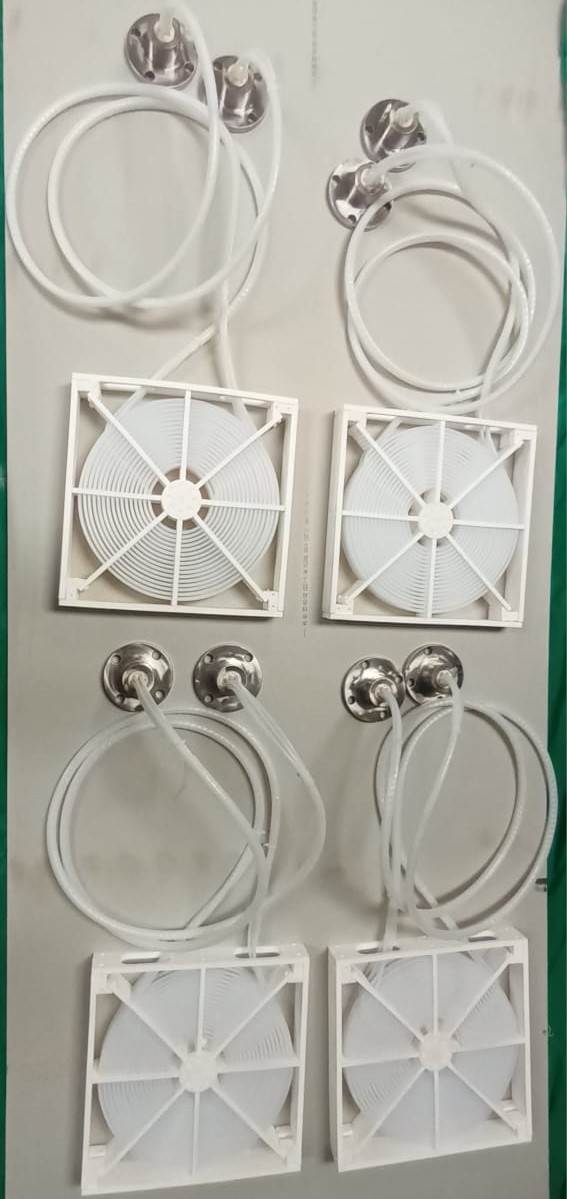

Teflon heating coil ,cooling coil and heat exchanger is used in plating tanks and process heating systems.

Technobel can design required heating coil or cooling coil teflon based and we require below data.

1. TANK DOT IN "mm :-

2. TANK WIDTH IN "mm :-

3. TANK DEPTH IN "mm"

4. SOLUTION LEVEL FROM TANK TOP IN "mm" :-

5. TANK "MOC :-

6. AMBIENT TEMP.IN "DEG C":-

7. REQUIERD BATH TEMP.IN "DEG C":-

8. CHILLER OUT LET TEMP. IN ° C :-

9. COOLING TIME IN :-

10. RECTIFIER CURRENT IN "A":-

11. RECTIRIER VOLTAGE IN "V" mb:-

Structure: Tube Heat Exchanger

Material: Imported USA Dupont (Teflon),Japan

Feature: Strong Anti-corrosion

Suitable for Temperature: 180-260℃

Teflon heat exchanger can heat, cool, evaporate and concentrate different corrosive liquids which are used for copper-plating and tin-plating. Teflon heat echangers are known as Teflon heating coil,Teflon cooling coil,PTFE heating coil,PTFE heat exchanger etc in electroplating industry

When immersed in liquid from 180°C to 260°C, Teflon heaters have strong thermal endurance.

Besides, Teflon heaters show excellent insulating property, non-sticky performance and ageing resistance while working that they can serve for more than 10 years even in strong corrosive gases and liquids or in poor air.

Features:-The advantages of our heat exchanger products over alternative designs include:

Low operating cost - The operating cost includes maintenance such as inspection, cleaning, downtime, and repair. This is primarily due to the relatively simple design that involves no plastic welding joints

No weld joints - Unlike metals that are subject to more rapid degradation under aggressive pickle bath conditions, Technobel’s heat exchangers withstand aggressiveness

Off the shelf repair kits -In case of an unlikely event of accidental tube damage, these kits enable a quick repair of the tubing

No tube bundling -The strong tubing coils are optimally spaced so acid flow and therefore heat transfer is maintained without fouling.

Constant operating efficiency - Fluoropolymers such as PTFE, FEP or PFA, are inherently “non-stick”, so fouling by scale deposition is minimized, assuring a constant operating efficiency that does not decrease over time.

performance:Making with the material of PFA, FEP, PVDF pipe, the heat exchanger’s quality is more excellent than the polytetrafluoroethylene (PT FE) heat exchanger material and full of higher thermal stability, plasticity, crack resistance and transparency.

Available Shapes:-1.Reactor tank or within the heat exchanger

2.Shell and tube heat exchanger outside the circle

3.Anti-static sleeve style for reheater and evaporator

1.The surface treatment of the chrome plating, acid tin, zinc, electrolysis, pickling, chemical plating, anodizing ,the chemical industry, medicine, food and heating, cooling, evaporation, concentration other corrosive solution.

2.Plating surface dispose solution of any heating, which is cooling, evaporation, concentration and sudden check.

Share this on:

Engineeredspecifically for your heating or cooling applications

Heavy wall, 18-gauge metal tubing available in steel, 316 stainless steel and titanium

Single point connections reduce the potential for leaks and simplify installation.

Every inch of coil surface is active exchange area.

100 PSI working pressure (steam or water).

0.75 square foot to 2.5 square foot of exchange area standard.

Share this on:

PTFE sleeved 304 stainless elements inert to most solutions up to 212 F (100T).

low watt density design 10 watts/square Inch (1.5w/cm').

Vapor resistant, flame retardant polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit.

Grounded Internal metal element and built In thermal protector.

Replaceable protector standard for solutions up to 180*F(82*C). Certification: 1309001,CE.

500 - 9000 watts, 120 to 600 volts (600 volts on 4500 watts or lower only)

Share this on:

Our anode baskets are made from Grade 1 titanium - a commercially pure quality which gives good resistance to most plating solutions.

The sides and base of our anode baskets are made from a solid sheet and the hooks are argon arc welded to ensure good electrical conductivity.

Basket Sizes

A Dimension: 6" (150mm), 8" (200mm), 10" (250mm) or 12" (300mm)

B Dimension: 1" (25 mm), 1.5" (38mm), 2" (50mm)

C Dimension: 12" (300mm), 18" (450mm), 24" (600mm), 30" (750mm), 36" (900mm), 42" (1050mm) or 48" (1200mm)

Share this on:

| Core Components | Motor |

| Voltage | 220V/380V |

| Power | Actual Power |

| Dimension(L*W*H) | Actual Size |

| Key Selling Points | Easy to Operate |

| Applicable Industries | Manufacturing Plant |

| Name | Small electroplating barrel |

| Application | For Gold Zinc, Nickel,Copper,Chrome Plating |

| Model | Customized |

| Material | 15 mm PP plate/PVC and customized |

| Available for | Zinc Plating /Copper /Nickel/Gold |

| Advantage | High quality, affordable price |

| After Warranty Service | Video technical support |