Share this on:

Product Introduction

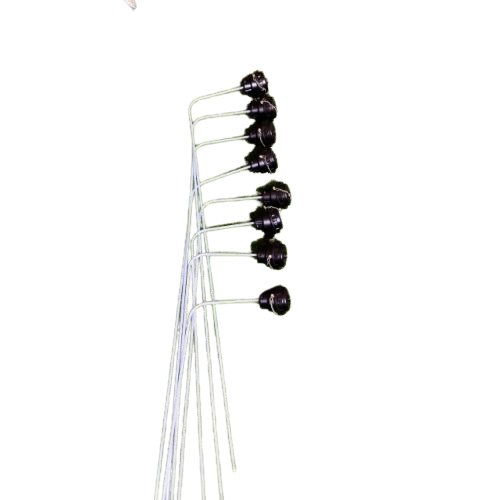

The Electro Plating Titanium Heater is a highly advanced heating solution that combines the exceptional properties of titanium with an electroplating process. Constructed from corrosion-resistant titanium, this heater is designed to withstand harsh conditions and provide reliable heating in demanding industrial environments. The electroplated layer enhances its performance by offering protection against corrosive substances, ensuring efficient heat transfer, and providing uniform heat distribution. With its rapid response time, versatility, and safety features, the Electro Plating Titanium Heater sets a new standard for efficiency and durability in industrial heating applications.

FEATURES

SUPERIOR CHEMICAL RESISTANCE:

Materials available for use in most aqueous alkaline solutions, plating solutions, and rinse tanks. Check solution recommendation chart or with your chemical supplier for proper sheath material selection.

OUTSTANDING PERFORMANCE:

Watt densities of 35 watts per square inch (5.4 w/cm2) ensure long service life.

EVEN HEATING:

Bottom design for even heating and varying liquid levels.

CORROSION RESISTANT HEAD:

Vapor tight, flame retardant polypropylene terminal enclosure with 3-foot (.9m) flexible PVC liquid tight conduit.

SAFETY FEATURES :-

Grounded construction:

Thermal protector built in. Replaceable PI fuse standard for solutions up to 180°F (82°C).

Non-floating construction.CERTIFICATIONS: UL (except steel sheath), CSA, and CE.

Sizes: 3,000 watts to 36,000 watts.

Voltages: 240 or 480 volts. 208, 380, 415, 600 and other voltages available. Three phase standard, Single Phase available.

Options Available (contact us):

Replaceable thermal protectors:

P4: for solutions from 180°F (82°C) to 230°F (110°C).

P5: for solutions from 230°F (110°C) to 300°F (150°C).

Resettable thermal protectors:

P2: for solutions up to 180°F (82°C).

P6: for solutions from 180°F (82°C) to 230°F (110°C).

P7: for solutions from 230°F (110°C) to 300°F (150°C).

1. Special configurations and lengths.

2. Longer wire and conduit lengths.

3. Lower watt densities for highly viscous solutions.

4. Temperature and level controls sized to match the heater.